O-My! Accurascale Goes Big With Cute Ruston 88DS As First O Gauge Loco

It's been a while coming, but we're delighted to reveal that our first O Gauge locomotive will be the venerable Ruston and Hornsby 88DS diesel mechanical shunter!

Why? Well, is there a more useful engine possible in 7mm? We wanted to "dip our toe" further into the O gauge water, and offering a cute small shunting locomotive for a very competitive price seems the ideal place to start!

Pre-Order Your Ruston and Hornsby 88DS Here!

A model that we begun work on in the days before the pandemic, the Ruston 88DS has been a long time in development as we look to further build our range in O gauge. Following surveys of a couple of prototype subjects, not to mention our usual extensive research and development, we kicked off our tooling earlier this year with the first tooling sample was just received ahead of the "Great Electric Train Show" this weekend.

Prototype History

Ruston & Hornsby Ltd, of Lincoln, was formed as the result of the merger between Ruston, Proctor & Co. Ltd and Richard Hornsby & Sons Ltd on September 11, 1918 and their first narrow gauge diesel locomotive left the works on September 1, 1931. In the summer of 1932, production was moved to the larger Boultham Works, where the firm were eventually to become Britain’s largest builder of diesel locomotives, with over 6,500 being built by the time production ceased in 1969.

Almost as soon as the firm’s 44/48HP 0-4-0 locomotives were making an appearance, an upgraded, more powerful 0-4-0 was on the drawing board.

Although many of the features of the 44/48HP were retained for the new 80/88HP, such as the chain drive and running gear, a new type of transmission was fitted, along with Westinghouse airbrakes. The new power unit, Ruston’s own 4VPB, delivered 80BHP at 1000rpm and was later supplanted by Ruston’s improved 4VPH that delivered 88BHP, but it required compressed air to be injected into the cylinders to be able to start. While running, an air reservoir was kept charged via the braking system, but after standing idle for a period the reservoir depleted and a secondary source was required to recharge the reservoir. This was achieved by fitting a small, secondary 1½HP ‘donkey’ engine, giving rise to a distinctive raised cover on the right hand side of the engine compartment, that differed in size and placement depending on the make of engine used.

Two basic weight options were offered for the 80/88HP, 17 tons and 20 tons; the difference being achieved by attaching weights to the outside frames, as well as to the front and rear buffer beams. In 1941, Ruston’s locomotive classifications were changed, with the 80/88HP becoming 88DS (with the narrow gauge versions being assigned the DSM and DSN suffix, and the broader gauges assigned DSW). Outward appearance changes to the ‘standard’ locomotives were mainly confined to the cab area, with examples from mid-1947 replacing the open cab with a fully enclosed cab that featured several ad-hoc styles of windows and fittings, depending on the customers’ requirements.

As a shunter, the 88DS was never going to be a greyhound in terms of speed, the four-speed gearbox delivering a maximum speed of just under 15½ mph, but it could deliver some impressive haulage figures, being capable of shifting a 510 ton train from a standing start on the level, down to a 56 ton load on a 1:20 incline. With the widespread delivery of the type, to all areas of industry and use, it is difficult to give an idea of a typical train, but photos showing consists of 8 covered vans, or mixed open/van consists of a similar number are common.

The first 88 to leave Ruston’s works was 192325 on 27 June 1938, bound for Tunnel Cement at Grays in Essex and the subsequent orders were spread across the country; from Kent and Dorset in the South, through the Home Counties, East Anglia and the Midlands, to the North of England and into the far reaches of Scotland. Customers tended to be those whose industries were reliant on internal railway systems, so the 88DS were in common use in various Gas Works, Paper Mills, Manufacturing Works, Refineries, Chemical Works, Quarries, Steelworks, Power Stations and Collieries.

The War Department/Ministry of Supply were a large customer for the type, with the 88DS being employed in Ordnance and Maintenance duties, often being flameproofed or provided with spark arrestors as a minimum. British Rail also took a number of 88DS into service, notably working at Reading and in the North-East from York and Hartlepool, to Newcastle.

Ruston also widely exported a large number of 88DS types: to Ireland, France, Holland, Portugal, Switzerland, Norway, Sweden, Turkey, Yugoslavia, Sierra Leone, Sudan, Kenya, Brazil, Argentina, India, Burma, Ceylon, Singapore, Malaysia, Indonesia, Australia, Rhodesia, South Africa and even Mauritius and Alderney!

The final 88DS, 518494, left Boultham Works on 29 November 1967, ending a production run of 271 locomotives, but a significant number have survived into preservation, albeit in varying states of completeness or operation.

Watch Our Launch Video To Find Out More!

Our First Production Run

Ruston 262997 was built new for the West Midlands Joint Electricity Authority, leaving Boultham Works on 27 January 1949 for the Birchills Power Station in Walsall. Birchills came under the control of the WMJEA in 1925 and in 1944 it was decided that a new Station, Birchills B, should be constructed. The new power station, called 'Walsall B', officially opened on 30th September, 1949, and 262997 was responsible for shunting at the new Power Station, still carrying its WMJEA legend despite nationalisation of the industry in 1948, where Birchills became part of the Midlands Region of the Central Electricity Generating Board. Birchalls burned ‘slack’ coal, a mixture of coal and coal dust which was delivered by road, rail, and canal. Located to the south of the former Midland Railway’s Wolverhampton to Walsall (Ryecroft Junction) line, the railway sidings and coal storage areas could be accessed from both east and west directions. The Power Station closed in October 1982 and the stub of railway serving it was closed at the same time.

Ruston 432477 was built new for British Railways, being delivered to the North Eastern Region Civil Engineer’s Department at Etherley Tip in Witton, County Durham on 5 January 1959. Expired track ballast and materials were dumped at Etherley in the post-war years, with the ballast being removed from the wagons, then passed over a screen to separate the 'fines' and muck from the bigger bits of stone. The fines would be dumped in the nearest low spot, whilst the ballast would be sold off for use as foundation material. The North Eastern Region employed a number of 88DS in the Civil Engineering Department, mainly being used for Permanent Way work, and 432477 was utilised around the region. By late 1969, the locomotive was laid up at Heaton depot and was finally scrapped in 1970.

Ruston 408493 was built new for British Railways Western Region, for use at the Signalling & Telecommunications Department workshops at Reading and was delivered on 19 January 1957. Taking the Departmental number 20, the locomotive spent its entire lifetime at Reading, housed under the Vastern Road bridge when not in use. Renumbered in 1973 under TOPS, to 97020, withdrawal came in April 1981 and the shunter was disposed of at Reading by Cartrights of Tipton in August 1982, being replaced by a Barclay Class 06 No. 06003, which was transferred to Reading from the Scottish Region.

Ruston 338413 was built new for the National Coal Board, for use at the East Cannock Colliery in Staffordshire, leaving the works on 23 April 1953. The locomotive stayed in the area for its working life, spending most of it in and around the NCB’s Hem Heath wagon workshops, where it was finally dismantled during 1982.

Ruston 412427 was built new for Bowaters Packaging Ltd, for use at their newly expanded Northfleet site in Kent, leaving Boultham on 25 March 1957. The Thames Mills site at Northfleet had resumed producing newsprint at the end of 1945, with supplies of pulpwood coming from Canada and Scandinavia, and the manufacturing output had doubled by 1957. The pulpwood was unloaded from the ships berthed at the deep water jetty on the Thames and from there, the raw material was conveyed to the mills by the internal railway system. With the gradual decline in newsprint production, Thames Mills was closed and transferred into the ownership of Bowaters’ Northfleet Terminals Ltd group and in 1981 412427 was donated by NTL to the fledging North Downs Steam Railway, then to Chatham Dockyard, Stone (Dartford), and Tunbridge Wells, before finally moving to Oswestry, Shropshire in 2007 for use on the Cambrian Railway.

Ruston 245034 was built new for the firm of Babcox & Wilcox Ltd in Refrewshire, leaving the works on 1 December 1947, where it was part of a fleet of 88DS utilised by the Boilermakers. The works opened in 1895 and covered 180 acres, one of the largest boiler making works in the world at the time, which was accessed from the 3 mile long Paisley & Renfrew line running from the east bank of the River Cart at Paisley to a wharf at Renfrew on the south bank of the River Clyde. Although B&W Renfrew manufactured huge boilers for both conventional and nuclear power stations, the line was completely shut in 1977, the same year that production at Renfrew was scaled back due to the recession, with 1100 workers losing their jobs.

Ruston 441934 was built new for Rowntree & Co. Ltd of York, being delivered on 14 April 1960 to join R&H 421419/1958 and 432479/1959 in the confectionery company’s fleet of locomotives as No. 3. In 1979, the York factory bought a new 0-6-0 locomotive and No.3 was transferred to Rowntree’s Fawdon factory in Newcastle. Rail services at Fawdon came to a halt on 30 January 1987, with No. 3 being handed over to the North York Moors Railway for preservation and after some years being moved about, in 2013 it was purchased by two members of the Derwent Valley Light Railway, Glynnis and Tony Frith. 441934 has now been named Ken Cooke, in honour of the former Rowntree’s York employee, D-Day veteran and holder of France’s highest military honour, the Legion d’Honneur.

Ruston 408496 was built new for the firm of Shanks & Co. Ltd at Longpark Pottery in Hillhead, Kilmarnock, leaving the works at Boultham on 24 January 1957. The locomotive was sold on, eventually ending up with NEI-Clarke Chapman at their Horseley Bridge works and has survived into preservation, currently residing at the Foxfield Railway.

Price, Delivery And Availability

Our adorable little Ruston is progressing nicely, with tooling already completed and testing of the first prototype samples well underway. We will continue this testing process and then progress to decoration stage, before signing off for production. Delivery at this time is envisaged for Quarter 1 of 2025. Both DC/DCC Ready and DCC Factory Sound fitted variants will be offered, with the latter making use of an ESU loksound 5 decoder and our own bespoke recordings of a real 80DS. RRP will be £229.95 for the DC/DCC ready locomotive and £319.99 for the DCC sound fitted loco.

Pre-order via our network of local stockists, or direct for no money down, or using our partial.ly system of flexible monthly payments at no extra cost below!

Pre-Order Your Ruston and Hornsby 88DS Here!

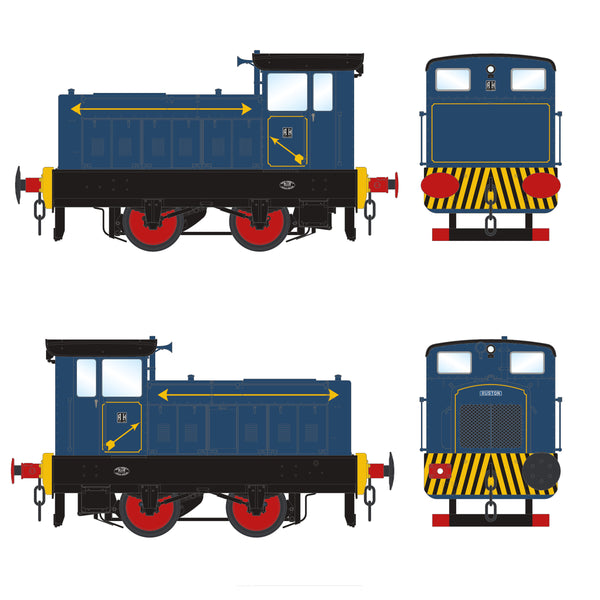

DESIGN SPECIFICATION and CONSIDERATIONS

- Die-cast metal chassis, body frame and footplate, with plastic cab and engine panels. Target weight of 475g.

- Scale length of 143.8mm over buffers, 54.85mm wide and height over cab of 70mm.

- Wheelbase of 40.54mm, for all vehicles, allowing operation over a minimum radius of 1020mm (2nd radius set-track).

- Choice of metal 3-link, or screw couplings for prototypical coupling.

- Brake blocks fitted and aligned with wheel centres for 0 Gauge, ensuring that they do not rub on wheel rims.

- Single style of 21mm solid wheel, correctly profiled both on the inside and outside and chemically blackened, set in blackened brass bearings or contact strips and conforming to Accurascale standards of 29.2mm back-to-back, on 4.763mm diameter axles.

- Fully detailed die-cast underframe with all cylinders, linkages and piping applied separately

- Eroded metal, plastic and wire detail parts, including (but not limited to) handrails, door handles, lamp brackets, brake gear, brake discs, draw gear, vents, louvres, radiator grilles and builders’ plates.

- Prism free flush glazing.

- Easily removable cab roof, to allow access to cab interior for customer detailing.

- Sprung metal buffers, and draw hooks.

- Authentic livery, markings and numbers, accurate to time period modelled, achieved by use of part painting and pad printing.

HIGH PERFORMANCE TRACTION and MECHANISM, TO INCLUDE:

- Centrally mounted, best quality 5-pole skew-wound motor, with flywheel, driving both axles.

- All-wheel pickup.

- Helical gear box for maximum performance and slow speed running.

- Gearing arranged so locomotive can achieve a scale maximum top speed of 15.4 mph (24.78 kmh), with a load of 1.1kg.

- DCC ready with PowerPack capacitor for uninterrupted power, or similar stay alive arrangement.

LIGHTING and DCC FEATURES, TO INCLUDE:

- Designed around PluX22 ESU Decoders with easy access to decoder via removable bonnet.

- Switchable shunting lights.

- Full cab interior lighting, set at correct colour temperature.

- Permanently fitted speakers.